Understanding the case for flushing

Any referenced datasets can be downloaded from "Module downloads" in the module overview.

The deterioration of pipes in a water distribution system is a major challenge for water utilities. Unidirectional flushing (UDF) can help to improve water quality.

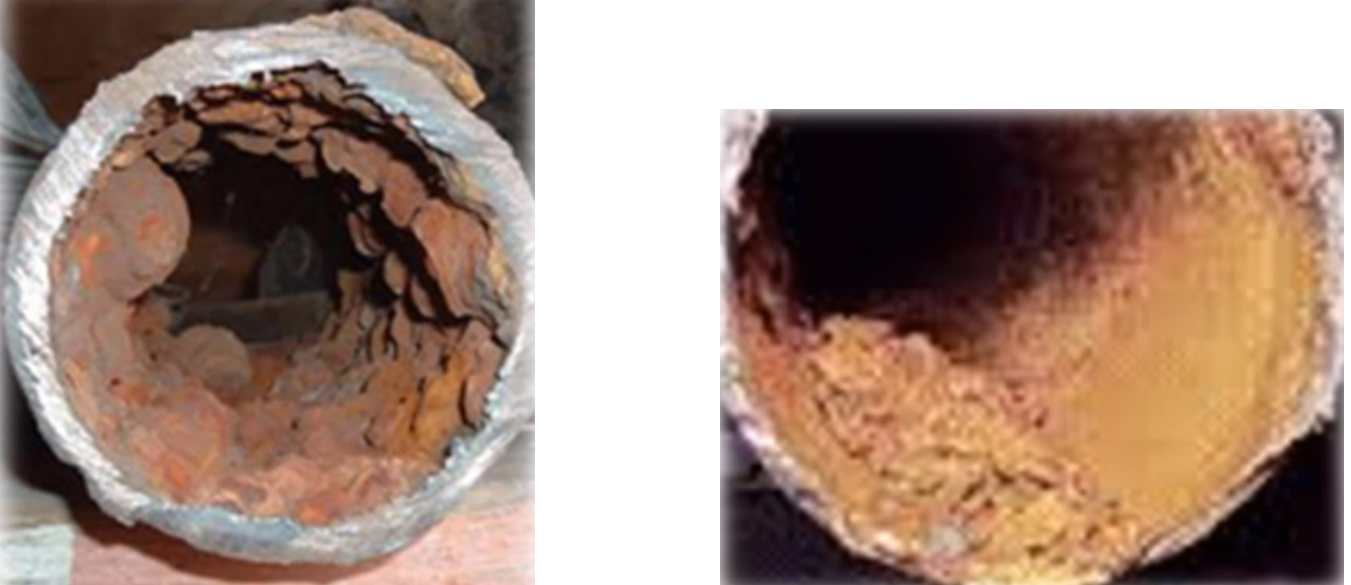

Pipe Deposits:

- In some pipes, depending on material and age, deposits can form on inside walls.

- Can cause hydraulic capacity to decrease over time.

- Can result from chemical precipitation, microbiological activity, and in the case of cast iron pipes, corrosion buildup.

- Deposits can increase pipe roughness and decrease effective pipe diameter, possibly resulting in:

- Inability to deliver fire flows

- Increased disinfectant demand

- Chlorine degradation

- Complaints about water taste, odor, and color

- Potential for public health issues

- Increased pumping costs

- Reduced hydraulic capacity

- Lower residual pressure

- Certain pipe materials, such as cast iron, are more susceptible to issues.

Unidirectional Flushing:

- Can prolong the life expectancy of a distribution system and reduce the potential for waterborne diseases.

- Can help remove biofilm growth and particulates that lead to chlorine loss, as well as taste, odor, and color concerns.

- In InfoWater Pro UDF, unidirectional flushing is performed by first isolating a portion of the distribution system, then opening fire hydrants or flushing valves.

- Can ideally create enough velocity to scour pipes and remove unwanted materials.

- Flushed water is then discharged through a hydrant.

- Generally begins in portions of system closest to water sources, proceeding to outward extents.

- Important to understand distinction among three flushing methods: UDF, conventional flushing, and continuous blow-off.

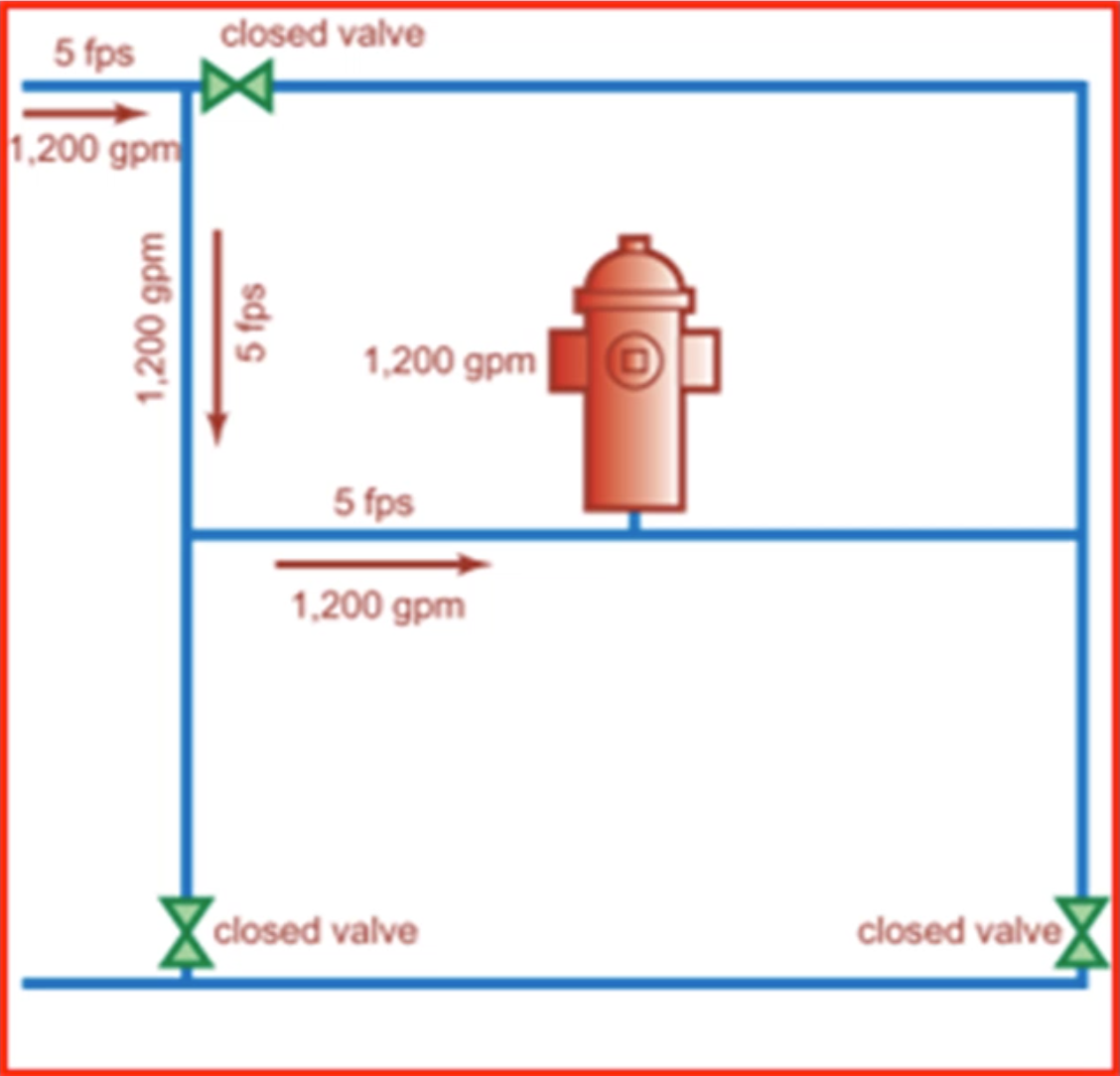

UDF Method:

- Most efficient flushing method.

- Involves systematic plan to direct flushed water in single direction along pipe to maximize velocity—can close valves and open hydrants to create one-way flow in water mains.

- Linear flow results in higher velocities, typically 5 or 6 feet per second.

- Maximizes linear velocity near pipe wall—ideal for removing biofilm and hardened corrosion materials.

- Flush begins at clean water source and ends at hydrant, so only clean water is used.

- Eliminates chances of dirty water and debris being inadvertently transported around the system.

- Not feasible in emergency situations, as it takes proper planning and time to carry out.

Conventional Flushing:

- No control of flow direction—for example, opening several hydrants at once in same area until water clears up.

- Effective for removing loose sediment, but less effective at raising pipeline velocities.

- Yields velocities of less than 2 feet per second, so not effective at removing deposits or biofilm.

- Can cause dirty water and debris to be inadvertently transported around the system.

- With lower velocities, often requires larger amounts of water, decreasing efficiency.

- Often used reactively to fix areas of poor water quality or in response to aesthetic complaints.

Continuous Blow-Off:

- Consists of a small, continuous or intermittent water usage to refresh the line.

- Usually seen as a short-term preventive strategy.

- Often used to solve stagnation problems.

- Comparatively low velocity of less than 1 foot per second, and can use large amount of water, resulting in poor efficiency.