& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

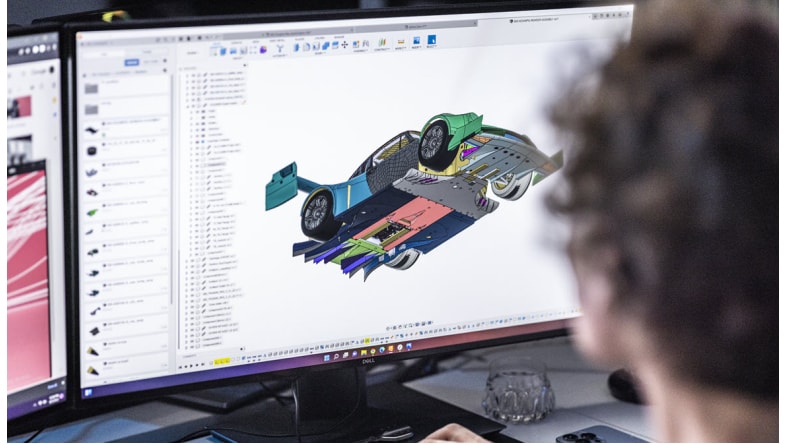

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

CNC machining, or Computer Numerical Control machining, is a manufacturing process that involves using computerized controls and machinery to remove material from a workpiece to create a finished part. It is a highly automated and precise method of manufacturing that allows for the production of complex and intricate parts with high accuracy and consistency.

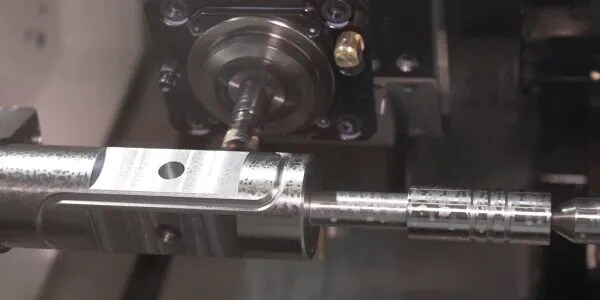

In CNC machining, a computer program is used to control the movement and operation of various cutting tools. These include mills, lathes, mills, grinders, and more. The program specifies the coordinates and movements of the cutting tools, which are translated into precise instructions for the CNC machine to follow. This enables the machine to perform operations like cutting, drilling, milling, turning, and grinding with a high degree of precision.

CNC machining offers high levels of accuracy making it suitable for producing parts with intricate geometries and tight tolerances.

Most CNC machines are primarily automated, reducing the need for manual work and minimizing the risk of human error.

CNC machining allows for multiple machining operations that can be programmed and executed at the same time, thus allowing for faster production times compared to traditional methods.

CNC machines can be programmed to create a vast array of parts, making it versatile across various applications and industries.

CNC machining makes sure that quality is consistent across multiple parts, as the same program can be used to produce identical pieces.

CNC machining offers quick setup and programming capabilities, thus making it well suited for rapid prototyping and small batch production.

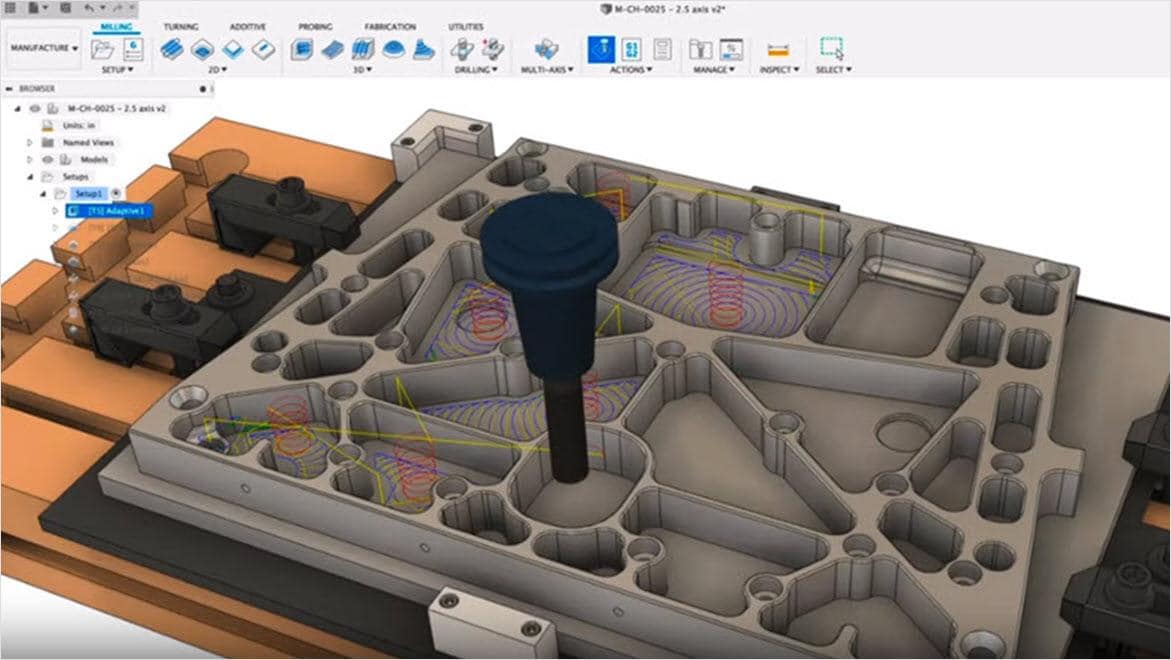

Autodesk Fusion integrates CAD and CAM to keep design and manufacturing connected. Once your 3D model is ready, you can set up your CAM workspace in Fusion. This involves defining the stock material, the coordinate system, and the workholding setup.

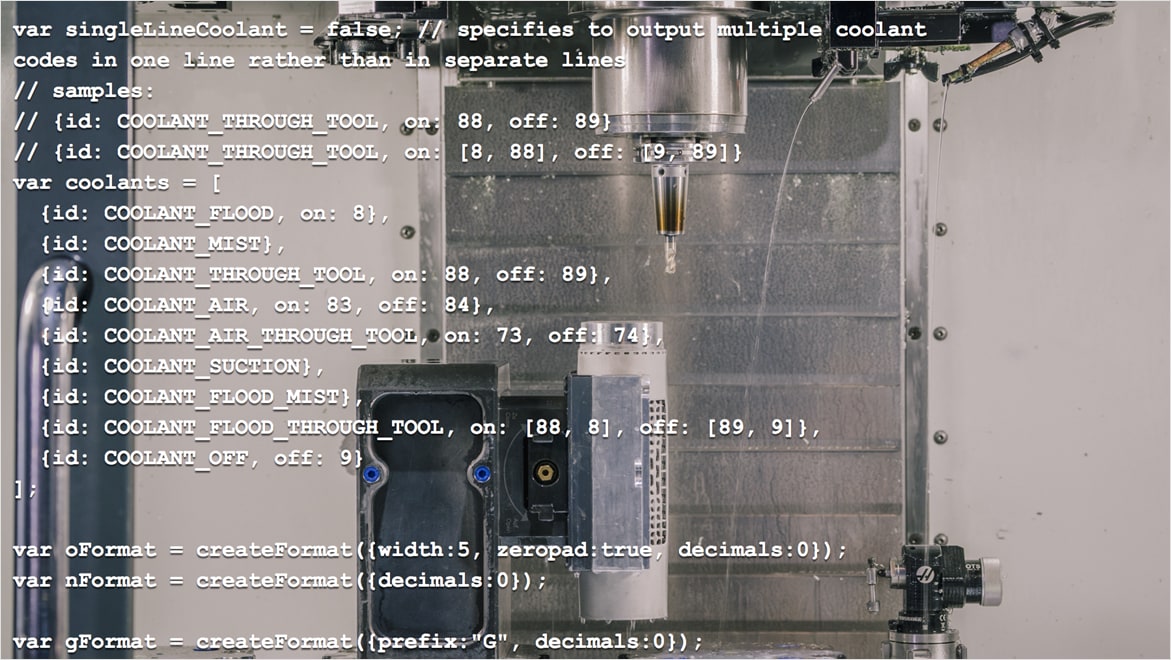

Toolpaths are turned into G-code, which is used to control the machine movements and generate the finished product at the end of the process. The manufacturing workspace in Fusion is responsible for interpreting toolpaths and exporting them as G-code for usage by a CNC machine.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

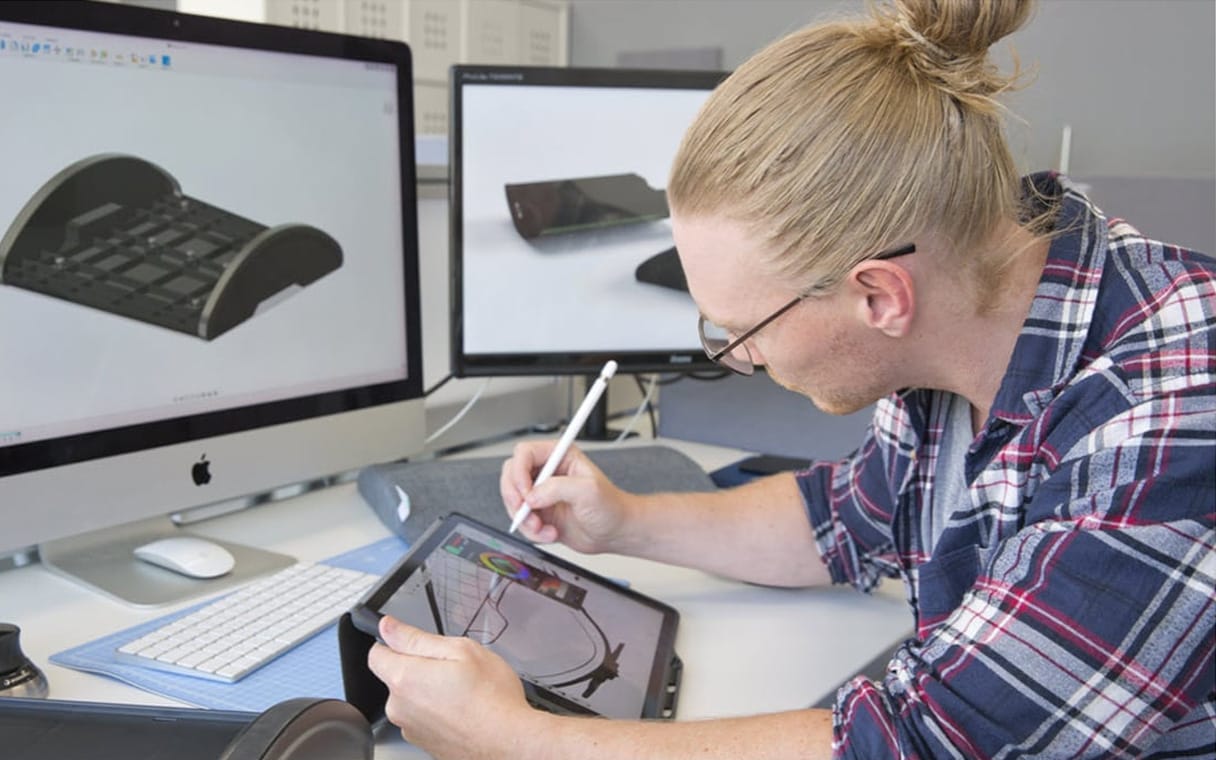

Fusion seamlessly integrates CAD, CAM, and CAE functionalities into a single platform. This means you can design your parts, generate toolpaths, simulate machining operations, and validate your designs—all within one software. This integration reduces the need for data transfers between different programs, saving you time and reducing the risk of errors.

Design changes are inevitable, but with the flexible modeling tools in Fusion, making alterations is a breeze. Make edits to your design, and the software will automatically update related toolpaths, ensuring that your manufacturing process remains synchronized with your design iterations.

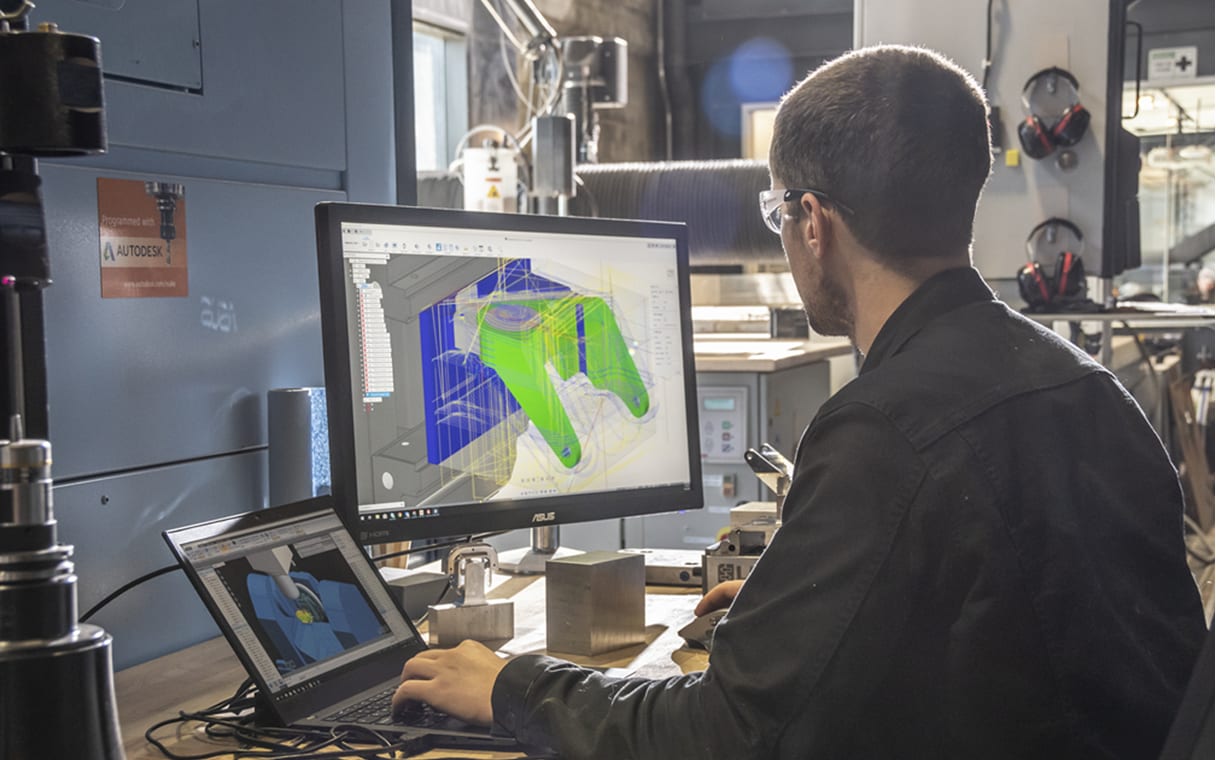

The CAM capabilities in Autodesk Fusion enable you to create intricate toolpaths for 2D and 3D machining, turning, and multi-axis operations. The software's adaptive clearing, contouring, and pocketing strategies optimize material removal while reducing tool wear and machining time.

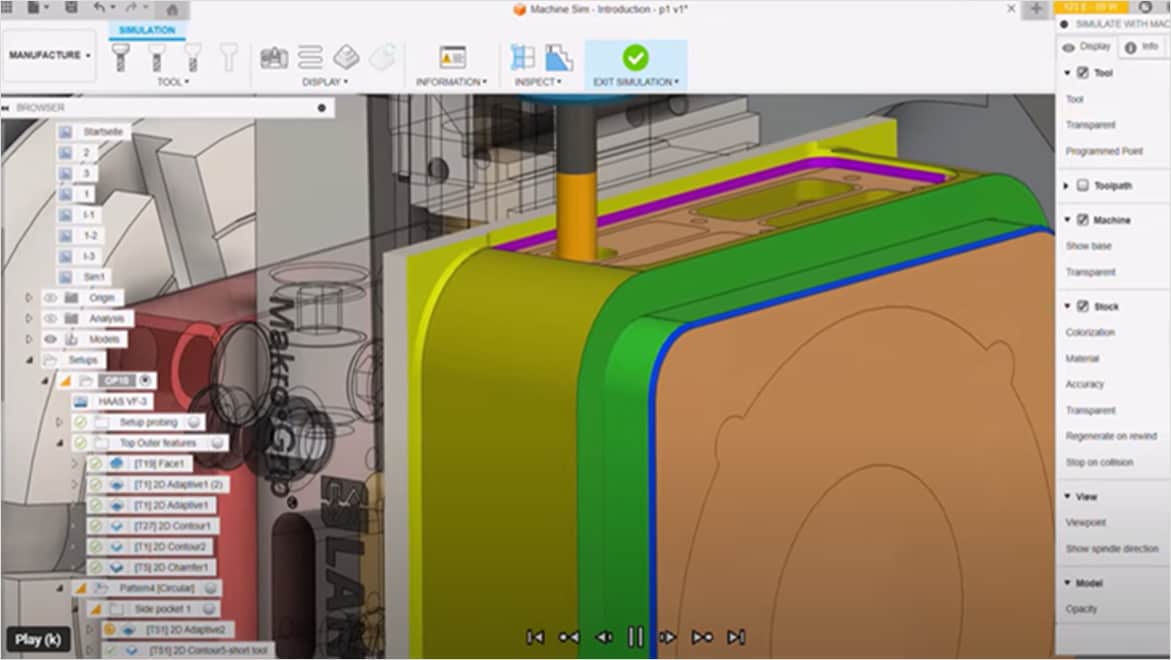

The simulation tools in Fusion allow you to visualize and validate your machining operations before cutting any material. Detect potential collisions, analyze tool engagement, and ensure that your designs will be machined accurately and safely.

Work with your team seamlessly, regardless of geographical locations. Fusion allows for real-time collaboration, making it easy to share designs, toolpaths, and project updates with your colleagues, clients, and manufacturing partners.

Adaptive clearing in Fusion is a high-efficiency roughing strategy design to remove large amounts of material quickly and consistently. It uses a toolpath that flows smoothly, maintaining an optimal tool load by taking deeper, lighter passes at faster speeds.

Adaptive clearing dynamically adjusts to the part geometry, clearing cavities and open pockets with efficient arcs and smooth transitions, which helps minimize tool deflection and heat buildup. By optimizing cutting conditions and balancing chip load, this strategy enhances both material removal rates and tool life, making it ideal for roughing complex 3D models efficiently.

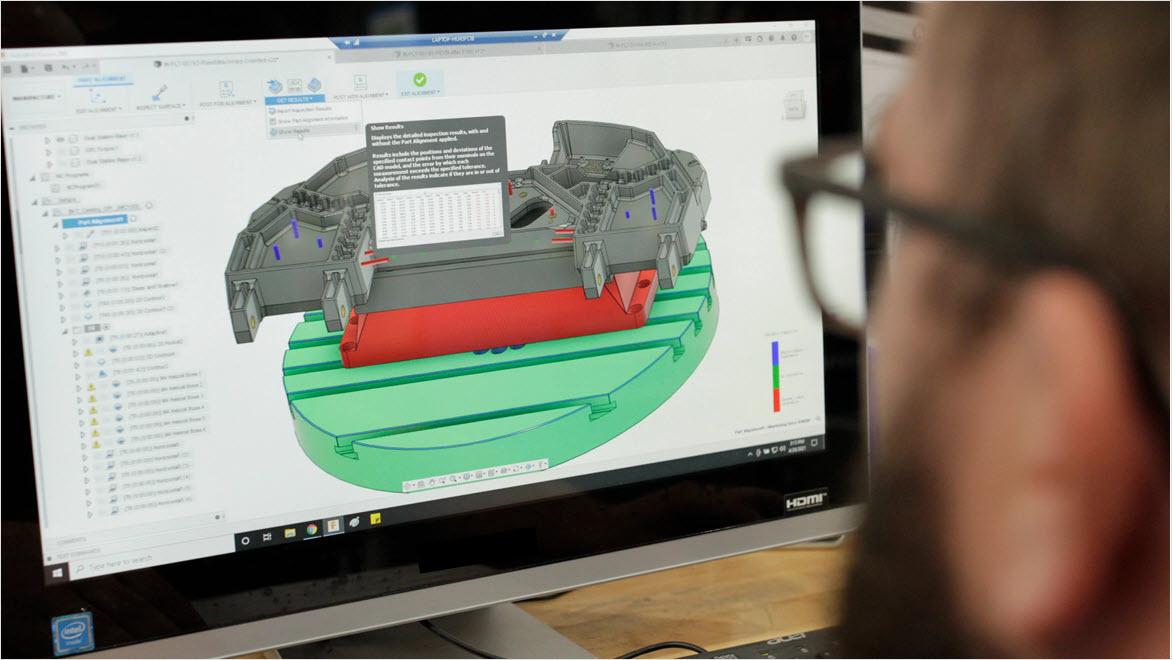

The advanced simulation and collision detection capabilities in Fusion help reduce errors during CNC machining. By virtually simulating the entire machining process, Fusion helps manufacturers identify potential tool collisions, over-travel, and other programming mistakes before they occur on the shop floor.

This minimizes costly machine downtime, prevents part damage, and ensures toolpath accuracy. With real-time feedback and detailed visualization, Fusion enables precise verification of tool movements and machining operations.

Autodesk Fusion makes post-processing and G-code generation easy providing highly customizable post processors tailored to a wide range of CNC machines and controllers. After creating precise toolpaths, Fusion converts them into machine-readable G-code, for compatibility with popular controllers. This seamless integration eliminates manual coding errors and accelerates the transition from design to manufacturing.

With the post-processing tools in Fusion, users can automate the generation of optimized, collision-free NC programs that precisely control machine movements, enhancing production efficiency and part accuracy across diverse machining operations.

Learn how 2-axis milling compares to 3-axis, and the advantages that 3-axis CNC machining has to offer.

The first step in many CNC machining operations is to remove as much material as possible. See how 'Adaptive Clearing' helps.

Positional 5-axis or 3+2, can offer advantages of simultaneous 5-axis without the additional complexity or high cost.

Turning, while still CNC machining, is different from milling. Learn about the five subfeatures of turning in Autodesk Fusion.

2.5-axis milling creates prismatic features at distinct Z levels. Even though the machine is only moving in two axes simultaneously, the CAM software is still used as the shapes created can be complex and high precision.

3-axis milling uses all three axes simultaneously. Software is used to generate these toolpaths since the surfaces are often complex.

4-axis milling adds one rotational axis to 3-axis milling. This is useful when parts are near cylindrical and can be used to create complex geometry or access multiple parts around workholding like a tombstone.

Simultaneous 5-axis machining uses all five axes at the same time to allow milling of complex shapes at high precision. CAM software is all but required to program these CNC machines, as the motion is complex.

BBi Autosport explains how Fusion enabled them to design the Hoonipigasus, “a car that can do nearly anything."

Check out how UK-based company Brown & Holmes doubled shop floor revenue with the Autodesk Fusion Manufacturing Extension.

See how aerospace and defense contractor Nerc Precision Engineering uses the Fusion Manufacturing Extension to increase business opportunities and output.

Learn important tools, best practices, and things to be aware of as you get up to speed with the manufacture workspace in Fusion.

Learn the differences between 2D, 3D, and multi-axis toolpaths and when’s the right time to use them.

Learn about the top 8 milling tools that every CNC Machinist needs to know about including end mills, face mills, fly cutters, center spot drills, and more.

These automation tools in Autodesk Fusion CAM will help you improve productivity when machining your next part.

Discover the benefits of 4-axis machining with Fusion, including enhanced precision, reduced tool deflection, fewer setups, and more.

NC-code is a CNC machine's language. Learn how to make your machine move using NC-code.

Yes, the simulation capabilities in Autodesk Fusion extend to intricate machining processes, including multi-axis milling and turning. Users can visualize and analyze the entire machining workflow.

Yes, Autodesk Fusion is built on the cloud thus enabling seamless collaboration among team members, making CNC machining projects more efficient, and collaborative.

Fusion simplifies CNC programming by generating toolpaths based on design models. Users can define machining strategies, simulate operations, and generate G-code for CNC machines.

Milling is one style of CNC machining. CNC machining is any process where a part is manufactured by a machine that is controlled by a computer. In milling, a cutting tool spins at high speeds and advances into or across the work piece to remove material. Other types of CNC machining include turning, routing, plasma cutting, and water jetting. Turning and milling can be combined into a single machine, as can additive and subtractive operations, creating even more complex styles of CNC machining.

Yes, Autodesk Fusion allows you to generate G-code directly from your CAM setups, simplifying the transition from design to CNC machining.

Typically, one of the largest costs associated with CNC machining is the CNC machine itself. Entry-level machines start around $5,000 with high-end machines reaching upwards of $500,000. The cost depends on factors like size, power, spindle speed, multi-axis capabilities, and accuracy. Once you have a machine, you will need to purchase cutting tools to machine parts. To generate the instructions required for CNC machining, it’s common to subscribe to a computer-aided manufacturing (CAM) software tool like Autodesk Fusion as well. So, while there’s no one size fits all answer, CNC machining requires some upfront investment to get started.

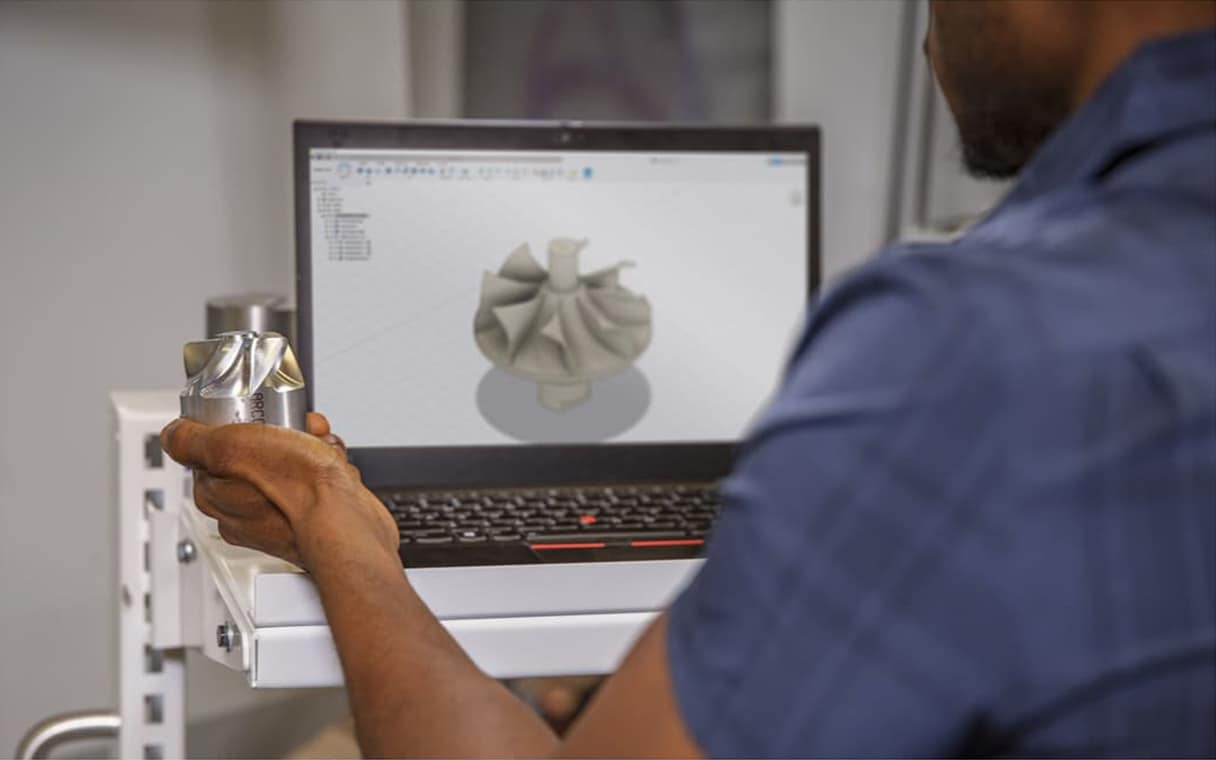

CNC stands for Computer Numerical Control. This means that a computer controls what the machine does, including but not limited to the spindle speed, feed rate, and position. To program the computer, often called a control, a person can use computer-aided manufacturing (CAM) software. CAM software generates a series of instructions called toolpaths and then generally uses a post-processor to translate that toolpath data into code the machine can read. Then a person would transfer that code onto the machine and run it to produce the final part.

Yes! Fusion includes a powerful and easy-to-use CAM solution that can control a wide variety of CNC machines. This includes mills, lathes, routers, mill/turn machines, plasma cutters, water jets, and lasers. Fusion also integrates CAD, CAE, and ECAD along with CAM into a single solution to reduce data loss and improve process reliability for CNC machining and other downstream processes.