Learn all about post processors, including what they are, why we need them, and how to use them in Fusion.

We created our Machining Fundamentals series to help you brush up on your CAM knowledge, whether you work in a machine shop or are just getting started. In-house machinists at our Birmingham Technology Center host each episode and provide a detailed overview of a tool/process. In the last edition, we covered lathes. Here we have an introduction to post processors, where you’ll learn all about post processor files: what they are, why we need them, and where to get them to use with Fusion.

Elevate your design and manufacturing processes with Autodesk Fusion

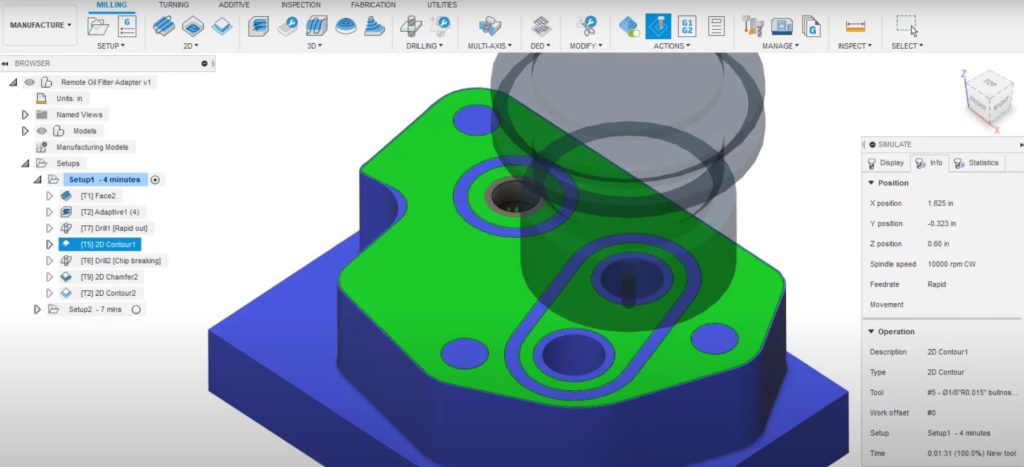

If you’re generating toolpaths with a CAM system, you need a way to turn them into code for your machine. Typically this is done by a post processor, another code file that turns toolpath data into machine code by converting the data into a specific file format required by the CNC machine. Post processors are often expensive, difficult to create, and hard to find support for. Fusion offers an online library with hundreds of free post processors that you can edit yourself to help make post processors more accessible to machinists across the industry.

Of course, that leaves a lot of people wondering where to get started with editing their own post processors in Fusion. The videos below address some of our most commonly asked questions.

What is a post processor?

A post processor is a specialized software tool that plays a vital role in the manufacturing process by converting computer-aided design (CAD) or computer-aided manufacturing (CAM) data into a format that CNC machines can understand. Acting as a bridge between your design software and your machine, the post processor takes toolpath information and generates machine-specific code. This is most commonly in the form of NC programs or G-code files. This code is what controls the CNC machine, informing every movement and operation.

Because every machine and controller can have unique requirements, post processors allow users to quickly customize the output to meet specific needs, ensuring the code is compatible with the intended hardware. Whether you’re working with a standard setup or have unique production requirements, post processors give you the flexibility to tailor the code, making them an essential tool for anyone looking to streamline the creation and control of CNC programs.

Find, install, edit, and request a post processor in Fusion

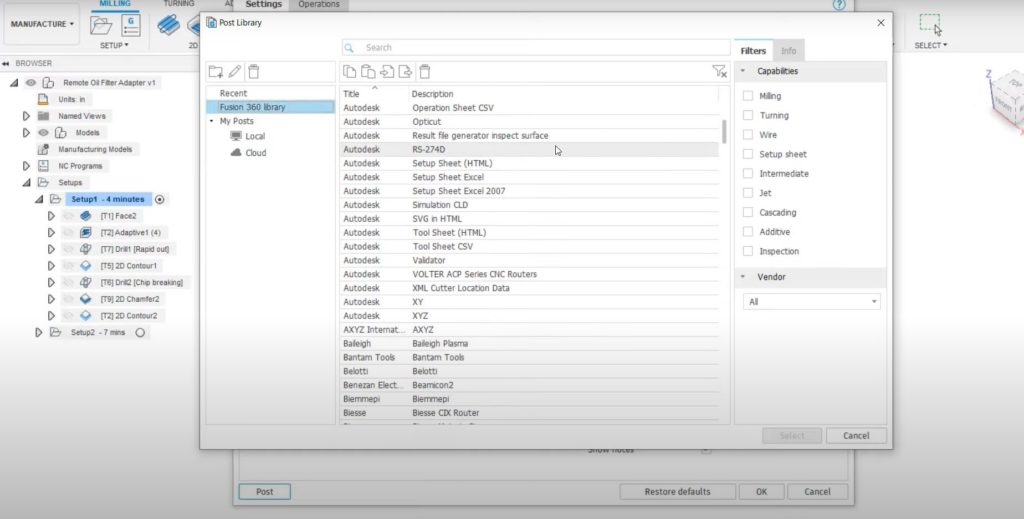

Find and install posts

Begin your journey with Fusion post processors by exploring the online library, which hosts the latest updates and machine-specific posts to enhance compatibility and functionality. These configuration files are typically stored in designated folders within the software’s file system, such as the PostP folder. Make sure that you reference the correct version of a post processor as it’s crucial for maintaining compatibility with your software and machine. Regular updates to post processors improve functionality and compatibility, and each version is marked in its configuration file for troubleshooting and checks.

Personal library for post processors

Once you install posts to your personal library, you can perform edits. It’s important to verify the configuration and test for syntax errors after installation. You can also install posts to your personal cloud library for access across multiple devices. For editing, utilize the Fusion Post Extension for Visual Studio Code, which simplifies locating and identifying parts of the configuration file and NC code. Alternatively, post processor files can be opened and modified using standard text editors such as Notepad++.

Editing posts

Users often start by copying an existing post processor and then customizing it to meet their machine’s requirements. Edits might include altering file extensions, machine parameters, or output formats. Adjustments to machine control settings within the post processor are sometimes necessary to ensure compatibility with specific CNC machines. Customizing tool-change commands or other instructions for the G-code output can be done within Fusion 360, making the creation of new or customized post processors straightforward.

Advanced services

If you prefer not to make your own edits, use the Post Services Marketplace to find paid customization from one of our partners. If you believe a key post processor is missing from our library, you can request its creation on the Post Processor IdeaStation.

For detailed guides on installing cloud posts, local posts, and finding, editing, or requesting post processors or customizations, refer to the written documentation provided. Dive in and enhance your machining process with customizable, efficient post processors in Fusion!

Understanding post processor sections in Fusion

Post processors in Fusion are organized into distinct sections, each dedicated to a specific part of the code generation process:

- Header section: Outputs initial commands at the start of the post-processed file to set up the CNC machine for the upcoming job.

- Tool change section: Manages the instructions necessary for switching tools during machining.

- Rapid move and feed move sections: Control the machine’s movements both between and during cuts.

- Footer section: Wraps up the program, ensuring that the machine finishes safely and correctly.

Understanding how these sections function is crucial for effective post processor editing. By knowing which part of the file to modify, users can tailor the output to meet the requirements of their specific CNC machines. For example, if your machine requires a unique startup sequence, you can adjust the header section accordingly. This targeted approach to editing enables users to optimize their post processors for improved performance and compatibility.

Enable 4th and 5th axes in a post

Many posts in our post library already support 4 and 5-axis code. However, these axes are disabled by default. In some cases, you can simply enable these additional axes through the Post Properties (more information on those in the section below this one). For example, assume your machine requires specific control instructions for the 4th axis; you should consult your machine’s documentation to determine the correct settings. In other cases, there are some edits you’ll need to make to the configuration file itself. When editing the configuration file, ensure that any additional axes or parameters are properly defined to guarantee correct operation. Additionally, certain parameters, such as line numbering or axis limits, may need to be controlled to match the requirements of your specific CNC machine. As always, if you make edits to a post processor please proceed with caution.

There is a written guide to enabling 4th and 5th axes that I recommend reading for more details on the properties of each axis

Using post properties in Fusion

Post properties offer a quick and easy way to customize your post processor without directly editing the configuration file. While you might feel hesitant about diving into the configuration file, post properties provide an alternative for making small adjustments right from the NC Program or Post dialog.

- Adjust variable output: Post properties can be used to modify variable outputs, such as tool positions or other dynamic parameters in the generated code. This feature allows for customization without manual intervention, using user-friendly tools.

- Customizing individual lines: Users can adjust individual lines of code or commands within the NC program through post properties.

- Using post properties: Watch the video provided for a more detailed explanation of NC Programs and how to effectively use post properties for your needs.

By using post properties, you can fine-tune your post processor for optimal performance and compatibility for your specific CNC machines.

Best practices for post processor editing in Fusion

Following best practices in post processor editing is essential for achieving reliable and efficient results. Here are some key steps to ensure your edits are effective:

- Use a dedicated editor: Start with specialized tools like the Autodesk Post Processor Editor or Visual Studio Code. These editors offer features such as syntax highlighting and error checking, making the editing process safer and more intuitive.

- Test thoroughly: After making any changes, rigorously test your post processor to ensure it generates the correct output for your CNC machine.

- Document changes: It’s crucial to document every change you make and maintain records of different versions of your post processor files. This practice allows you to track modifications, share your edits, and revert to earlier versions if needed.

Common challenges in post orocessor editing and how to overcome them

Editing post processors can be tricky, especially for beginners. Here are a few common challenges and how to tackle them:

- Compatibility issues: Ensure your post processor works with specific CNC machines or controllers can be tough. Even tiny differences may lead to errors in the output code.

- Understanding code: The structure and logic of post processor code can be intimidating if you’re not familiar with programming.

- Mistakes: Errors made during editing can result in faulty code that might not run correctly on your machine.

Solutions: To overcome these challenges:

- Utilize available documentation.

- Seek support from your software provider.

- Engage in online communities where experienced users share advice.

- Use debugging tools to identify and fix errors in your code.

Optimizing post performance in Fusion

To get the post out of your post processors in Fusion, it’s improtant to optimize them for your specific machines and manufacturing needs. Here are some ways to get the most out of your post processors:

- Customization: Adjusting your post processor code lets you utilize your CNC machine’s full capabilities, enabling advanced features like high-speed machining or multi-axis operations.

- Fine-tuning: Fine-tune parameters such as feed rates and spindle speeds to match the material you’re working with. This customization can enhance both efficiency and product quality.

- Regular updates: Keep your post processors up-to-date to ensure they remain compatible with the latest versions of your CAM software or CNC machines. This practice helps prevent issues stemming from outdated code.

By continuously refining and modifying your post processors in Fusion, you can boost machine performance, reduce production time, and maintain a competitive edge in your manufacturing processes.

Get started with post processors in Fusion

If you’re looking for more information on post editing, take a look at this comprehensive guide written by our post experts. Many commands and features in post processors are thoroughly documented for user reference. Users should also pay attention to notes and annotations provided in the documentation for additional guidance. You may find a note or TOOL_NOTES section in the configuration files, which provides important information about tools or toolpaths. Other software, such as BobCAD-CAM, also offers robust post processor editing and customization capabilities.

I would also recommend this comprehensive video by John Saunders of NYC CNC. He goes into detail about the Visual Studio Code extension. The Post Processor Forum is a great place to ask questions as you get up and running. Users can seek help with debugging post processors and troubleshooting issues. I also recommend searching the forum for your post or question before posting. There are literal years of helpful information already there!

Finally, here is a direct link to the Online Post Library which contains links to many of the resources above in the upper right corner. Fusion supports a wide range of CNC machines through its extensive library of post processors.

Ready to start editing your own posts? Users can control power settings for tools such as lasers or jet cutters within the post processor configuration. Creating new or customized post processors in Fusion is easy and straightfoward. Get started today!